Harbor Freight Table Saw

Table Saw

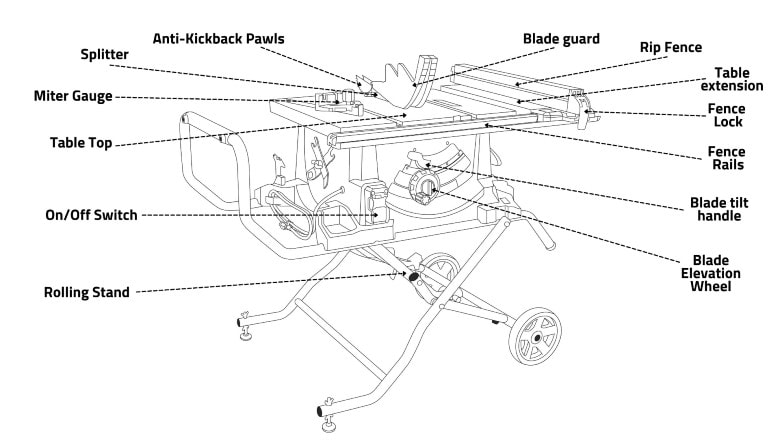

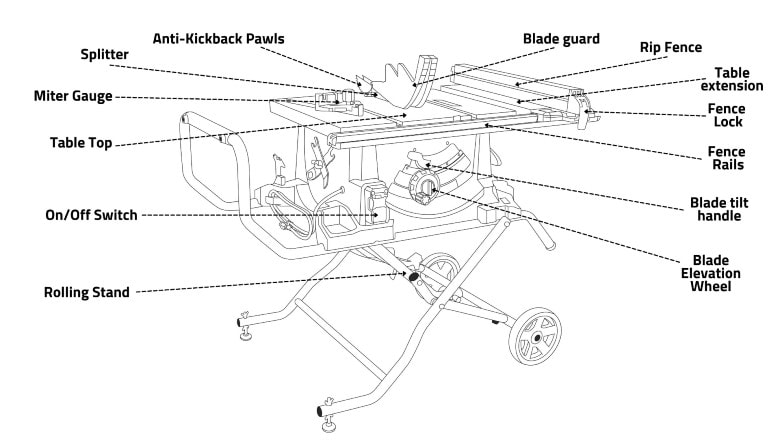

A table saw (also called a table saw or table saw in the UK) is a woodworking tool consisting of a circular saw blade mounted on a tree and driven by an electric motor (directly through a belt or gearbox). The blade protrudes from the top of the table to support the material to be cut, usually wood. For most modern table saws, the cutting depth can be changed by moving the saw blade up and down: the farther the saw blade extends from the table, the deeper the cut in the material. On some early table saws, the blade and shaft were fixed, and the table moved up and down to more or less expose the blade. Control by adjusting the blade angle. Some early saws tilted the table to control the cutting angle.

A table saw is more than just a table with fast rotating blades. By using the suitable table saw accessories and accessories, you can upgrade and upgrade your table saw.

Table saws are mainly used for grooving, but this is not all you can do with this very important woodworking machine. You do not have suitable accessories.

Splitter

A splitter is comparable to a riving knife except it doesn’t affix to the saw’s arbor, sort of a riving knife. This implies that, unlike a riving knife, a splitter stays in the same place irrespective of the blade’s height. This could leave the workpiece to pinch in between the blade and splitter when the blade is ready to low.

Anti-Kickback Pawls

Anti-kickback pawls are another guard designed to stop kickbacks and are generally attached to the riving knife or splitter. The anti-kickback pawl employs two pieces of metal with teeth angled away from the blade. This permits you to feed the workpiece into the blade but causes the teeth to catch the workpiece should kick back out.

Magnetic Switch

A magnetic switch works to safeguard you from injury should the facility venture out while using the table saw. Essentially, if you lose power, the magnetic switch prevents the saw from automatically turning back on when the ability does.

Table Extensions

They are an often optional accessory that permits you to extend the rip capacity of a table saw. They connect with the table of a table saw, generally with a rack and pinion system. This permits you to regulate the dimensions of the extension as required, with some extensions providing for a maximum 52 “rip capacity.

Featherboard

Featherboards are another safety component that acts as a fence of sorts on top of the workpiece. More often than not, purchased feather boards attach to the fence. They help keep the workpiece straight along the fence’s edges. Thanks to the angled fingers, a feather board also helps prevent kickback.

Crosscut Sled

A crosscut sled is somewhat just like a fence except it moves with the workpiece. Crosscut sleds are useful because the longer fringe of the workpiece tends to run with the grain. You position a crosscut sled behind the workpiece to feed the workpiece into the blade.

Push Stick

Push sticks are safety accessories that allow you to feed the workpiece into the blade without having to fret about getting your hands and fingers close. While a push stick may be thick enough to be considered a “block,” the standard push stick is supposed to be used for creating thinner rip cuts. This ensures that you can simply maintain control over the smaller workpiece without having to position your finger near the blade.

Dust Bag

Unlike other forms of power tools where a bag attaches to the tool which sucks up and collects dust, a table saw’s vacuum bag sits under the saw. In this instance, the vacuum bag catches falling dust particles as they sift through the saw’s body. While not terribly helpful in keeping the cutting area clear, a bag makes cleanup much easier.

Dust Chute

While some table saws try and target dust at the source with dust collection mounted to the blade guard, that’s away from the norm. Traditionally, table saws include a dust chute embedded within the housing of the table saw which collects dust because it falls through the body. Table saw dust chutes are generally available in sizes of 1 14″, 2 12 “, and 4” with many models with multiple sizes.

Dado Blade

As mentioned prior, dado blades are accustomed to cutting trenches out of workpieces and are available in a number of different varieties. The wobble dado blade is the standard model and sees the blade spin in an “S” pattern that leaves a small curve within the cut. Stacked dado blades are available in a collection with blades and chippers that you can just add or remove to regulate the scale of the dado cut. Stacked dado blades leave a straight edge and are more precise.

Mobile Base

Opposite the cupboard, a mobile base could be a part of some table saws that make it way more portable than it otherwise would be. In confine mind, most table saws with a mobile base attach to the bottom, though some have the bottom built directly into the housing. Generally, a table saw with a mobile base is supposed to be taken to the employment site. As such, these table saws find most of their use with contractors and other professionals.

Summary

As you’ll see, once you break down a harbor freight table saw into its various parts and specs, what was once a confusing topic is fairly straightforward. Outside of industry-specific terms and jargon, table saws really only involve a few unique concepts. Now that you simply know all about table saw basics, you ought to be well-armed to shop for the simplest table saw for your workshop.

CHICAGO ELECTRIC 10 In. 15 Amp Benchtop Table Saw for $114.99

Buy the CHICAGO ELECTRIC 10 In. 15 Amp Benchtop Table Saw (Item 63118) for $114.99 with coupon code 30252072, valid through June 30, 2020. See the coupon for details.

Compare our price of $114.99 to Ryobi at $229.00 (model number: RTS22). Save $114 by shopping at Harbor Freight.

This industrial benchtop table features an extra-wide die-cast aluminum table to support many ripping applications.

The CHICAGO ELECTRIC 10 In. 15 Amp Benchtop Table Saw (Item 63118 / 45804 / 63117 / 64459 / 68827 / 69480 / 97896) has a 4-star rating on HarborFreight.com. Stretch your dollar further at Harbor Freight. Shop our Items Under $10 Sale, going on now through June 30, 2020.

Important Factors to contemplate

When buying a table saw it’s important to stay some important factors in mind:

Portability – Will you wish to maneuver your table saw often or will it’s stationary? There are larger table saws that might do best in an exceedingly stationary place. If you would like to maneuver your table saw around or take it with you there are compact and portable options too.

Ease of Use – If you’re a beginner you’ll want to seem into a less powerful table saw, this can be because when an influence tool has more power, it will be hard to regulate.

Motor – The more power a motor has, the higher its performance is going to be. However, confine mind that when a motor is more powerful it can sometimes make the tool harder to regulate. For more information on what proportion power a table saw needs, check out How Much Power

Does a Table Saw Need?

Power Source – There are cordless and corded table saws out there. Cordless power saws are great if you wish to move your table saw quickly and simply, however, you’d need some batteries readily available for a full day’s work. A corded table saw makes moving the saw around harder but you don’t must worry about having enough batteries.

Durability – Since power tools like table saws don’t seem to be cheap, you would like to form sure the table saw you’re looking into buying is durable.

Why you thought to Buy a Table Saw

There are quite a few reasons to feature a table saw in your workshop. Here are some of them:

Very versatile – Table saws have many uses. they’re very customizable and that they are useful on job sites, in workshops, etc.

Powerful – Table saws will allow you to tackle a number of the toughest jobs with ease.

Great for larger materials – Most table saws have more table space compared to other saws. this permits you to handle larger materials easier and more safely.

There are many pros, but there’s one con that may affect people’s decision when it involves buying a table saw:

Dangerous power tool – Table saws are more dangerous than something sort of a miter saw, this might be a priority for somebody who doesn’t feel very confident around power tools.

HARBOR FREIGHT TABLE SAW REVIEW

The harbor freight table saw is one of the most important pieces of equipment in the carpenter’s arsenal because it is used in almost every project. Whether you are making a bookcase or a chair, you will most likely still use a table saw, but it is important that you invest your money in a high-quality table saw, which will bring you excellent results. And will serve you for a long time. the weather. Experience and uptime I decided to review Harbour Freight’s table saws to help you make the best purchase decision.